Mining

Equipment

Other industries

-

7539 De la route Kasapa

Quartier Gambela I,

Commune et ville de Lubumbashi,

Province du Haut- Katanga en République Démocratique du Congo

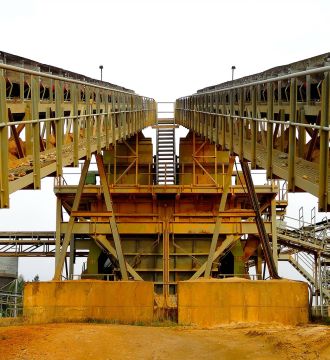

Drilling, crushing and mineral-processing equipment

Crushing and grinding equipment

Crushing and grinding equipment is used in the construction industry, as well as in mining areas for crushing rocks. In the first case, crushers and mills are used in the manufacture of dry mixes, foam concrete, cement, gypsum, lime and other materials. The use of crushing and grinding equipment in the mining industry makes it possible to obtain the necessary fractions of marble, granite and other rocks. Grinding lines are also in demand in areas for processing secondary raw materials.

Types of grinding and crushing equipment

Manufacturing companies produce grinding and crushing equipment of periodic or continuous operation with an open or closed cycle. Such equipment provides dry or wet grinding of rocks, as well as various building materials. In industry, grinders of ball, screw, bead, jet, hammer, disk and some other types are used. The working housing of the mills is made in the form of a drum, cylinder or cone, and the grinding surfaces are in the form of a ball or rod. In some models, self-grinding is used and there are no grinding media. Loading of materials is carried out mechanically or with the help of pneumatic systems.

The agitated grinding equipment currently on the market can be divided into two categories: gravity mills and fluidized mills. In gravity mills with agitation of the grinding medium, the grinding media are driven by a rotating screw, which creates conditions for grinding the material. On the contrary, the operating principle of fluidizing mills is based on the rotational motion and fluidization of the mixture of pulp and grinding media.

Efficient equipment is what allows you to provide maximum return at the lowest cost of operation. The quality and economic performance of the plant depends on the quality of this equipment.

We supply a wide range of equipment that is used for crushing granite and boulders, as well as sorting crushed stone.

Drilling equipment

Drilling equipment has been widely used in various industries: engineering surveys, construction, geological exploration, hydrogeology, seismic exploration.

We offer drilling rigs: small-sized, self-propelled, rotary and tracked all-terrain vehicles. Modern drilling rigs meet the requirements for safety and efficiency of the work performed.

Cooperation with buyers includes an individual selection of drilling equipment.

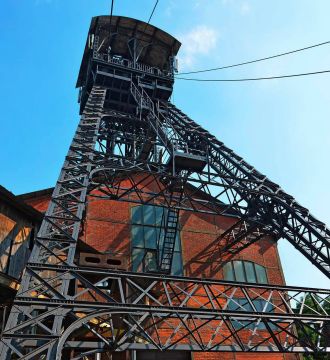

Mining transport equipment

In the mining industry, all products must have a special safety margin, guarantee safe, uninterrupted operation and maximum cost-effectiveness, including equipment that works daily to lower and lift people and transport rock and materials. Often the work is carried out in especially difficult conditions, with constant, extreme load.

We offer mine hoisting equipment with a substantial safety margin:

- Cages mine

- Shackles

- Planting cams

- Mine parachutes

- Suspension devices

- Counterweights mine

- Mine skips

- Linear stoppers

Mining excavators

The modern mining industry, according to the method of mining, is divided into two main areas: open-pit mining, when materials are mined in a quarry, and underground, with the construction of mines. The technique used in mining is also divided - for each type of work, their own, often very specific machines are used. Moving down the chain of equipment from top to bottom, in the first place are overburden excavators used to excavate rocks and minerals in open-pit mining.

The hydraulic excavator is increasingly seen in the quarry, one after another, miners are abandoning the obsolete cable excavators, the so-called "mechanical shovels" - until recently the most common type of excavation and loading machines in open pits around the world. Once upon a time, any work began with them, for example, coal mining, but over the years, this type of equipment began to lose in terms of technical parameters to hydraulic models.

When the volume of work is not so large, mining excavators of a smaller class are used. This technique includes the Komatsu PC3000 hydraulic excavator. The heart of the machine is the company's own 12-cylinder, water-cooled, direct-injection engine with high performance.

Spare parts:

- Screen dampers

- Metal structures

- Supporting frames for screens

- Conveyor rollers

- Rotors for crushers

- Gears for screens

Enrichment and sorting equipment

Benefaction equipment is a complex of technical elements that are used in the procedure of processing minerals in order to obtain a certain concentrate. Often, the benefaction equipment is referred to as mining and processing equipment. It can confidently include gravity, crushing, magnetic, electric, dewatering, grinding, sorting equipment and others.

The popular types of equipment for industrial purposes:

- The latest laboratory equipment.

- Industrial equipment.

- Powder materials.

- Apparatuses for waste processing.

Laboratory equipment includes crushing and grinding units, shrinking and separating machines, devices for material dehydration. Industrial workshops also actively use screens, vibrating screens, crushers, feeders, various types of separators.

Our main goal is to provide the client with only the highest quality equipment at the best prices. Moreover, these are exactly the devices that can quite easily enter both the already formed production cycle and the newly opened production.

We cooperate with

world-class suppliers